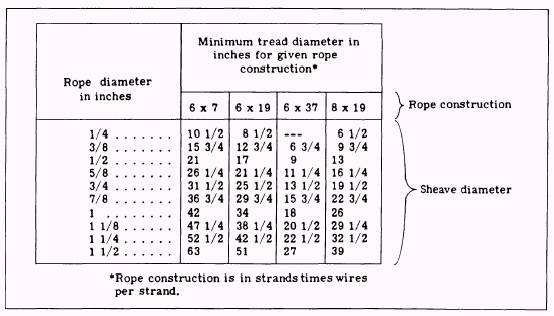

Sheave and drum diameter all wire ropes operating over sheaves and drums are subjected to bending stresses which eventu ally cause the wire rope to fatigue.

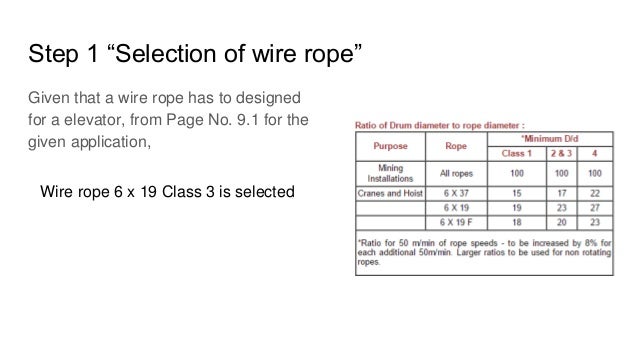

Minimum drum diameter for wire rope.

Because there are many different types of equipment and many different operating conditions it is difficult to identify the one specific size of sheave or drum.

Charles missouri 63303 866 852 9714.

Sheaves drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope.

Due to tolerances on diameters and variety of constructions of wire rope it is difficult to calculate the maximum length of wire rope that can be spooled on a reel or drum.

If the loads are light or the speed slow smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are.

2086 exchange drive st.

The severity of these stresses are directly related to the rope load and the d d ratio or the ratio of the tread diameter of the sheave or drum d to the diam eter of the rope d.

In general the larger the size of the drum or pulley with respect to the wire diameter the longer the service life.

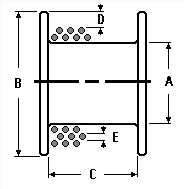

Sheave design is critical to wire rope service life bending wire rope over sheaves and drums.

1 over the actual wire rope diameter groove depth h.

Performance of wire rope in a machine is affected by design of its sheaves and drums.

Information about design of sheave and drum diameter the shape of the groove profiles and corresponding radius the drum pitch and the fleet angle is given in this article.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results because of the other factors affecting the useful life of the rope.

Table for value of constant.

Industrial wire rope 7390 harrison avenue cincinnati ohio 45247 888 345 0919.

The following are recommended values.

The bend radius of the rope is approximately half of the minimum recommended pulley tread diameter.

The tables below provide the minimum recommended pulley diameter.

1 5 x d or d x 2 sheave throat angle.

Minimum 0 53 to 0 535 x d maximum 0 55 x d recommended.